Products

Our rubber items vary from simple circular shapes to complex layouts and outlines laser engraved. Working thicknesses range from 0.2 mm to 20 mm.

NIS S.r.l. molds articles with different inserts: aluminium, iron, plastic and magnets, with diameters from 6 mm up to over 200 mm

Raw materials used by NIS are both standard and customized elastomers, designed according to our recipes to respond to Customers’ specific needs.

Main ones are NBR, EPDM, HNBR, FKM, VQM, CR and silicons.

Inserts are made in aluminium, iron, plastic and magnets, They are treated to prevent corrosion and painted to improve bonding with rubber.

- 01-Production of rubber technical items

- 02-Production of metal-rubber technical items

- 03-Mold construction

- 04-Construction of moulds and fine blanking

Workforce

NIS is specialized in the production of rubber and metal-rubber technical items Total workforce: 85 people, 21 employees and 64 manpower. Horizontal machines are ran by five persons per shift, 24 h/day

Production line

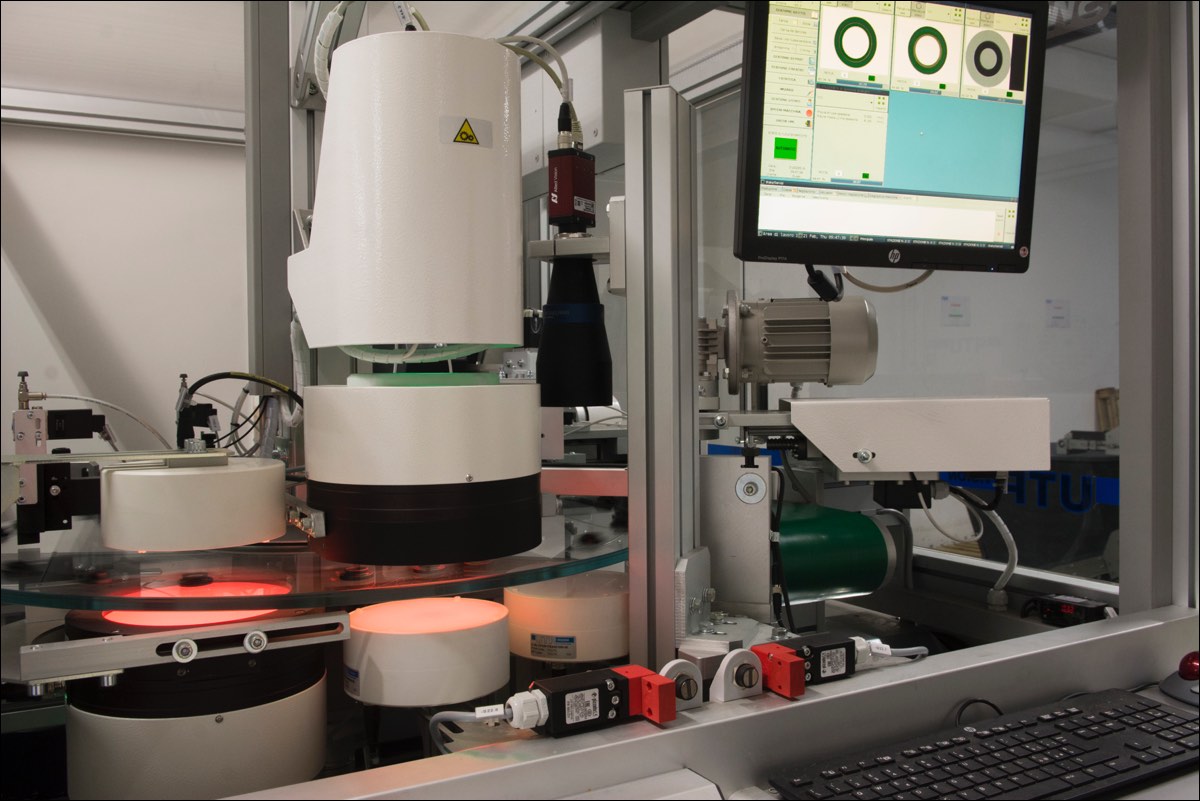

Our production line has 34 horizontal machines and 16 vertical ones, most of them network connected to track process data. We have installed three automatic UTP machines for the dimensional and surface defect control. In the equipment portfolio there are CNC machines for grinding / cutting of the sealing lips and special control machines with the specific purpose for the individual articles.

Company

NIS is a company with deep roots, with over than 50 years of experience in this industry. Currently employes 75 persons, aged lower than 40 years in average, the majority are women.

NIS exports over 80% of its turnover all over the world: main destinations are Europe, Far East, India, North and South America.NIS products have different applications: Automotive, machinery and household appliances.

NIS has a UNI EN ISO 9001: 2015 and IATF 16949: 2016 certified Quality Management System.

Tecnology

Mould construction

We are studying and creating the best solutions for each type of mould, bringing to perfection the techniques in the design and construction step of moulds to be used mainly for the automotive, precision pneumatics and household appliances field.

Molding

NIS has an horizontal molding production line, dedicated to automatic production, and a vertical one, used for metal-rubber components. They are all under SPC control and process parameters are recorded.To complete the production, items are punched with pneumatic machines or cut to create sealing lips with particular shapes.

Finishing

To complete the production, the articles are sheared/blanked by means of the pneumatic machines, or cut to have the sealing lips with the particular geometrical designs. We have a department specialized in for post vulcanization and additional treatments and also a laser engraver, used both to cut articles with complicated shapes and to engrave the batch number on the piece and ensure its traceability. The control department has three automatic UTP optical vision machines for automatic visual and dimensional control.

Labwarehouse

NIS have a internal lab equipped with digital measurement machines to control incoming materials, semifinished and finished products. Control department has an optical UTP machine for visual and dimensional automatic controls. Our Lab is equipped with optical measuring systems, digital dynamometer and others to perform the measurements required by customers

Warehouse

Our warehouse is handled with dynamic allocations and controlled by a wi-fi terminal that allows optimal FIFO rotation. Each package is identified with a barcode and the traceability chain is guaranteed for each working phase from raw material to finished products.

Shipping

Once all our products are accepted in our warehouse, they are ready to be shipped. NIS exports all over the world: main destinations are Europe, Far East, India, North and South America.

Location

Do you want to work with us?

P.IVA 00178370052

REA AT 52043

Capitale soc. € 101.920 int. vers

Quality, Health, Safety and Environment Policy

Email: [email protected]

Pec: [email protected]

Tel: +39 0141.669115

Fax: +39 0141.669656

Strada per Cortandone 75

Monale (AT) 14013

Lun- Ven dalle 8.00 alle 17.00